Overview

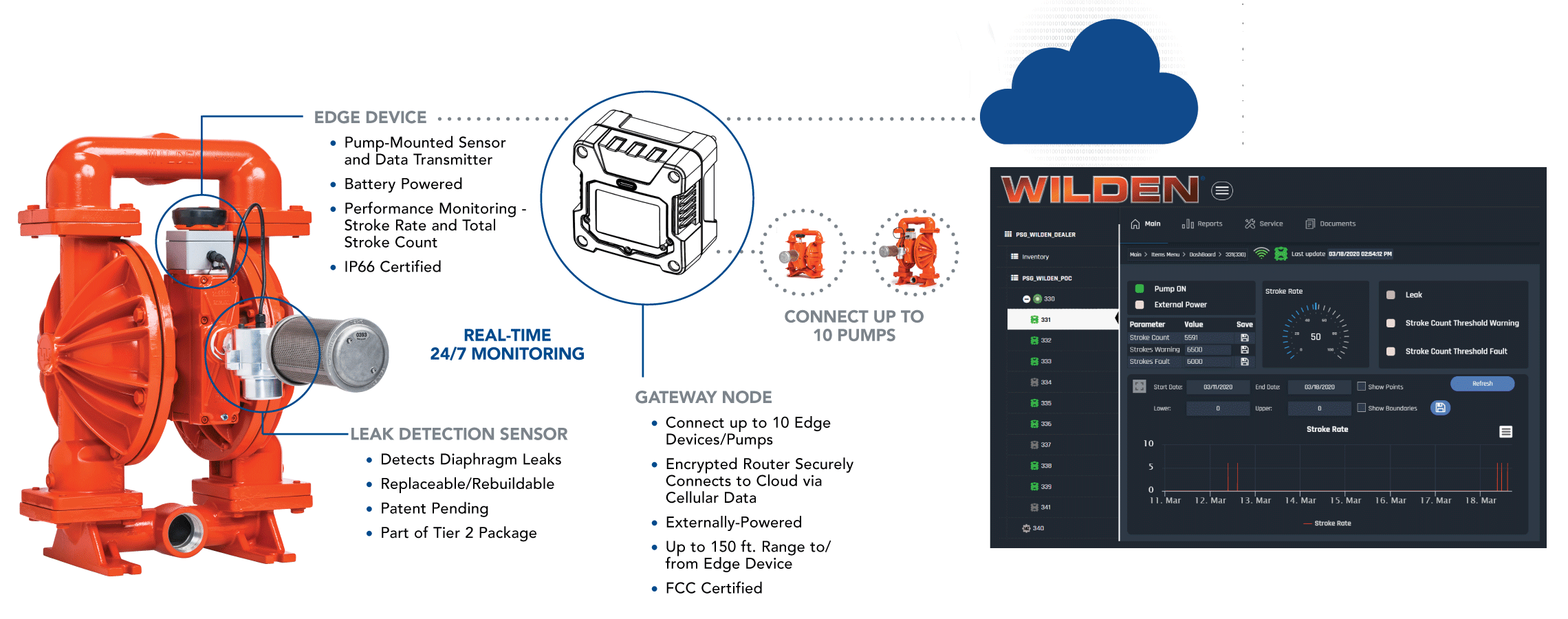

Wilden SafeGuard Remote Performance Monitoring and Alert System

The Wilden SafeGuard is the industry’s first AODD Internet of Things (IoT) enabled remote performance monitoring and alert solution. It is a true game-changer in optimizing AODD pump performance, reliability, cost of operation and maintenance. SafeGuard is an all-inclusive monitoring system that tracks, records and alerts customers to key AODD pump performance indicators at all times of operation via continuous Cloud connectivity as a way to address and prevent operational shortcomings that can result in costly pump failures.

User Interface

Wilden AODD pumps’ health and performance is displayed and summarized on the Wilden SafeGuard User Interface service where you can view the status of your whole fleet of connected pumps down to the details of a single pump. Capabilities include:

- Fleet Management View

- Pump Dashboard

- Review Maintenance and Operation History

- Color Code Indicators of Status

- Customizable Parameters, Pump Naming, Users, and Alerts

Benefits and Features

The design and operation of the SafeGuard system allows for complete 24/7 real-time monitoring and alerts related to a number of critical performance parameters for the pump (diaphragms, balls, seats). These readings can show the user such things as:

- Leak detection to indicate diaphragm leaks and failures, preventing product loss and safety hazards

- Stroke rates to monitor changes to highlight performance abnormalities

- Stroke count for batching and setting maintenance schedules

- Real-time alerts via SMS or email to indicate any noteworthy change in operation that may be a precursor to pump or component failure

- Plug-and-play design for easy set up and easily retrofittable to current installations

- Maintenance records that can indicate patterns and help manage preventative maintenance plans