Features

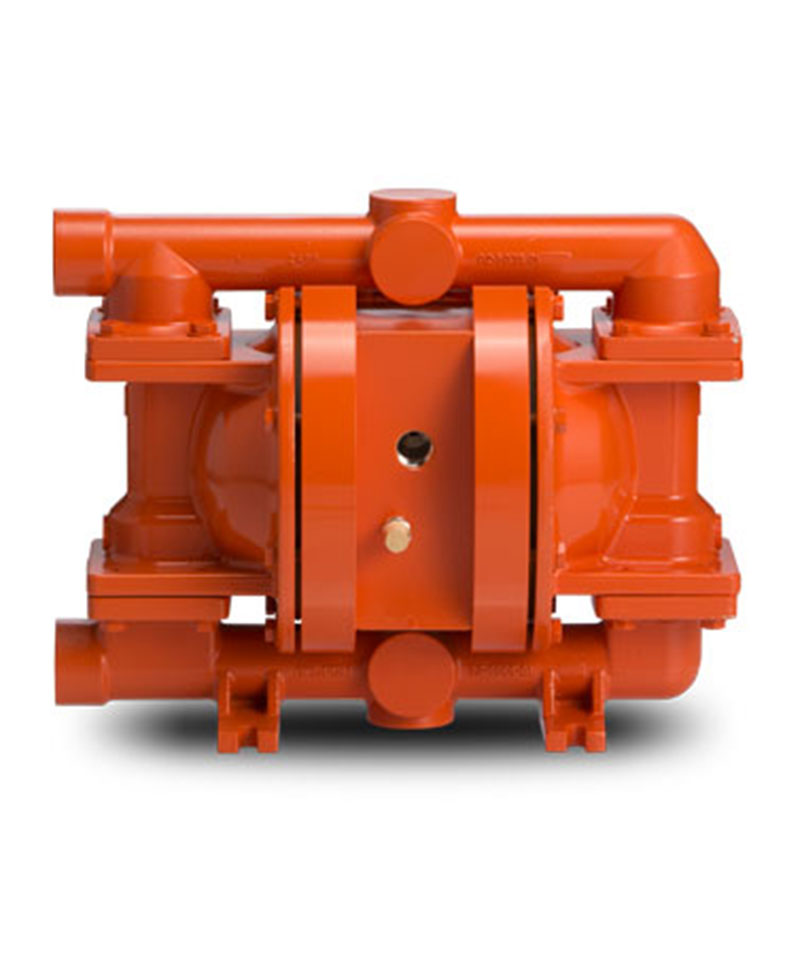

P220 1”/25 mm FIT Metal Pump

The Wilden® FIT metal pump sets the new standard for pump performance. A reliable performer, this pump has greater flow rates compared to earlier Wilden pumps and its closest competitor.

The FIT design uses a wetted path that minimizes the number of fasteners and allows for single socket reassembly for faster, easier maintenance compared to legacy Wilden pumps and competitors.

FIT pumps are designed for superior containment, ease of maintenance, and are a direct replacement for existing threaded pumps in the field.

- 220 designates NPT or BSPT threaded inlet/discharge liquid connections

- Available with Pro-Flo® Air Distribution System

- Superior containment and direct replacement for existing bolted pumps