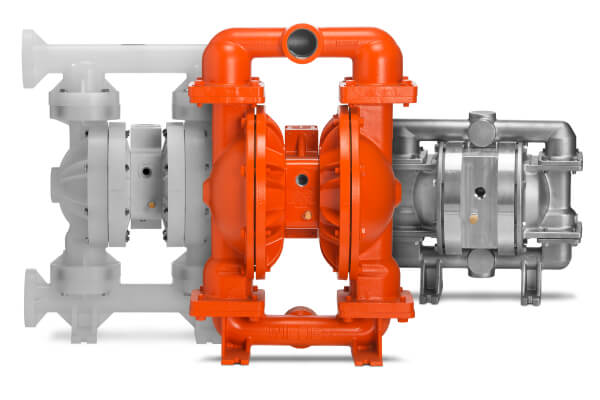

Product Description

The Zenit UNIQA – ZUG-CP [Chopper] electric submersible pump excels in heavy-duty applications, particularly in industrial and wastewater treatment settings. Specifically designed to tackle challenging liquid mixtures, it efficiently manages wastewater containing solid particles, fibers, and other debris.

- Channel impeller in hard cast iron as standard

- Chopper sistem able to cut particles of any shape of proportion

- Efficiency of hydraulics only 3/5% less than that of a normal channel impeller

- Liquids containing solid parts and fibres

- Suitable for sewage, lifting of not strained black water

Motors are designed with the aim of achieving the Premium (IE3) efficiency class according to the EN 60034-30 standard and guarantee high performance with low energy use. There are various types of hydraulics, to adapt perfectly to any type of application.

Models are available with:

- vortex impeller (ZUG V) with full free passage

- channel impeller (ZUG OC) with anti-clogging and anti-fouling system

- high head impeller (ZUG HP) capable of high hydraulic performances

- impeller with grinding system (ZUG GR) for use with soiled liquids and filaments

- impeller with Chopper sistem (ZUG CP) able to cut particles of any shape of proportion

Depending on the service required, each model comprises a motor-hydraulics combination chosen to provide optimal performance at the duty point, low energy use, and high reliability, thanks to the use of the materials best suited to the type of application.

The entire range is available in the DRY version, which requires no external liquid inputs and allows the electric pump to operate continually even if partially submerged or installed in a dry chamber.

Models available in IECEx UNIQA WET II 2G Ex db h IIB T4 Gb / UNIQA DRY II 2G Ex db h IIB T4 Gb – II 2D Ex h tb IIIC T135°C Db certified version.