Product Description

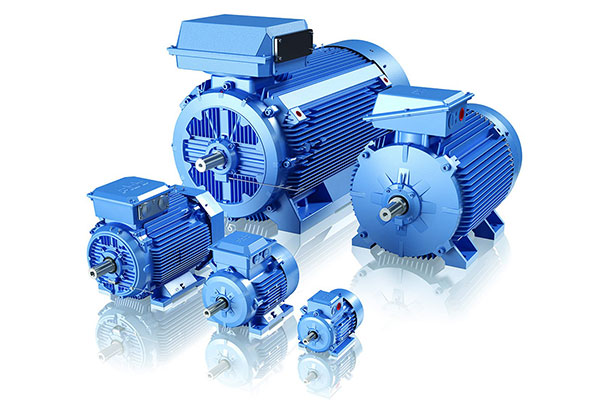

The Robox Lobe is able to reach up to 1,000 mbar(g) and vacuum up to 500 mbar(a) with a maximum capacity of 10,500 m³/h.

Unique design, best in class footprint, low noise, easy installation, easy to service and maintain access throughout the range.

The new Robox blower unit design (sizes 3.0, 3.5, 4.0, 5.0) allows you to fit either a lobe or a screw airend into our engineered Robox enclosure. To accommodate this innovation, our teams performed a complete package redesign. You can call it thinking outside the box to create our best Robox yet.

In additionthe new Robox Lobe sizes 1.0 and 1.5 have been ingeniously redeveloped to boast footprints reduced by up to 20% without compromising on performance, making them the perfect choice for installations where every square inch counts

Unique Design, Best-in-class Footprint

Thanks to its exclusive features, the new Robox Lobe blower unit has compact dimensions with the possibility of side-by-side installation. It is easy to be installed with no requirements for ducting. The Robox Lobe blower’s compact dimensions will optimise your floor space usage.

One Package Two Technologies (Sizes 3.0, 3.5,4.0, 5.0)

Take advantage of the one solution for both lobe and screw blower technologies. Whether revamping plants, or your processes, you can review and compare each technology’s benefits for your operation before you commit to buy.

Small Footprint for Minimal Space Requirements (Sizes 1.0, 1.5)

The new additional frames — 1.0 and 1.5 — mark the smallest options within our lobe blower range. The distinctive configuration of the Robox lobe package minimizes its footprint while concurrently preserving and enhancing performance. Depending on the lobe blower dimensions, we’ve managed to reduce the overall footprint by an impressive 20%.

Low Noise

Low noise emissions are ensured by our new discharge and suction silencer design. In addition, canopy enhancements provide noise reduction thanks to special sound proofing material and upgraded panel thickness. In addition, the enclosure air inlet and outlet ducts are muzzled with a lined single-chamber plenum and lined bends.

Easy Installation

Save time and money thanks to the easy and flexible installation of the new Robox Lobe blower. Handle the Robox with ease utilizing the rigid base which has dedicated channels for forklifts. Place it on any even surface, with no need for special foundations. Thanks to its compact design, the Robox can be quickly and easily integrated into your existing system.

Accessible Service and Maintenance

All maintenance operations are easily performed from the front with the removal of the front panel or for bigger frames with the removal of side panels.

For frames 1.0 and 1.5 the all the maintenance tasks, such as oil change, belt replacement, and air filter installation, can be effortlessly carried out by simply opening the rooftop and removing the front panel.

Additionally, air end overhaul and motor repositioning are conveniently achieved through unrestricted top and front access.

RBS – Oil-free Premium Airend

The Robox Lobe blower unit accommodates the RBS airend with three special profile lobes. Combined with a low pulse system, the lobes reduce the residual pressure pulsation of the conveyed gas to less than 2% of the operating pressure.

The RBS airend is equipped with splash-lubricated helical tooth synchronized gears for optimum rotor timing. High quality lobe profile rotors are controlled by three-dimensional instruments for top volumetric efficiency. Durable shaft design compliments the RBS’ reliable operation. The RBS airend is also oil-free certified, Class 0 certification, according to ISO 8573-1.

New Compact Suction Silencer

A newly designed Silencer is equipped with a dedicated filter cartridge for improved reliability and quicker maintenance. This minimises pressure drops. Noise reduction is provided by a new absorptive and reactive internal resonance chamber design.

Robust Discharge Silencer

A Reactive discharge silencer with increased thickness and spark arrester. This design prevents contamination of conveyed gas with sparks generated by the blower. Costly spark traps are no longer necessary.

Check Valve

The VRC check valve, engineered by Robuschi, is a proven and robust component designed to ensure reliable backflow prevention in demanding applications. Now strategically positioned within the device, it allows for quick access, making inspection and replacement faster and easier than ever. This thoughtful integration reduces downtime and simplifies routine maintenance, contributing to overall system efficiency.

Lubrication System

Robuschi’s dual splash lubrication system offers a compact, reliable, and maintenance-friendly solution for optimal performance. By eliminating the need for an external oil circuit, this system ensures consistent lubrication of critical components while minimizing complexity. Its simple yet effective design reduces maintenance requirements and enhances long-term reliability, making it ideal for continuous operation in industrial environments.

The user-friendly Robox Connect touch screen features an intuitive menu, offering a real-time view of the operation of the Robox Lobe and Screw units. This interface enables continuous monitoring of your equipment, facilitating early detection of issues and malfunctions to safeguard your investment. Additionally, the controller efficiently manages a range of operating functions accessible both from the built-in touch screen and remotely.

The embedded communication protocols are Modbus RTU, TCP.

Main Controller Functions

-

Multiple language configuration

-

12 analog and digital inputs / outputs

-

Interval maintenance

-

Parameter data transmission via Modbus RTU, TCP.

-

Parameter trends

-

Warning & Alarm detection

-

Data logger for service troubleshooting

-

Suitable for any kind of starter device

What Are the Controlled Parameters?

-

Suction pressure (P1)

-

Discharge pressure (P2)

-

Oil injection pressure (P3)

-

Discharge temperature (T2)

-

Oil sump temperature driven side

-

Enclosure temperature (T5)

The new Controller connects the Robox unit with the new Robuschi cloud. Smart and proactive real-time monitoring service designed to offer comprehensive and up-to-the-minute data crucial for maximizing the efficiency and operation of your equipment.

The Robox Lobe blower unit is available in a new plug and play version: simple, reliable and a great value for your money.

This includes:

- Premium frequency converter for maximum performance and reliability

- Electrical cabinet with IP54 protection degree and a forced cooling system

- Modular installation close to Robox unit or in another location via wired connection for maximum flexibility

- Programmed control panel for process optimization and regulation

- Industry 4.0 solution with data transmission through the most popular communication protocols (Modbus, Profibus-Profinet, Canopen)

- Preset frequency converter for peace of mind

- Additional system for continuous monitoring of main parameters (optional)

- Quick start guide included

- EMC certification