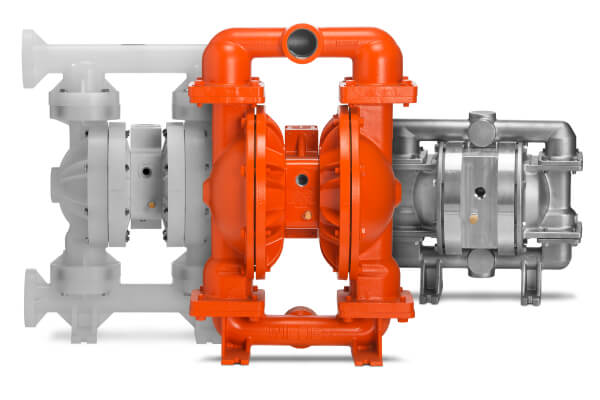

Product Description

The Wilden® P820 bolted metal pump, also known as FIT, sets the new standard for pump performance. Featuring an enhanced flow path design, Wilden’s bolted-construction pumps offer improved flow rates (up to 35% over competitive models) as well as improved diaphragm life. Wilden’s bolted pumps are also designed for superior containment and have the exact bolt down footprint and inlet/discharge connections as Wilden clamped pumps for easy replacement.

CE Mark (Conformité Européene – European Conformity)

Wilden Pump & Engineering LLC has met the criteria for placing the CE mark on our product line. On December 3, 1999, Wilden fully self-certified its product line by meeting all the regulations of the Machinery and PED (Pressure Equipment) Directives. Every pump manufactured by Wilden will now receive the CE mark. Each pump box will also include a Safety Supplement manual in the eleven official languages of the European Community. This CE mark certification is indicative of Wilden’s pledge to providing our distributor network with all the sales tools necessary to excel in a global economy.