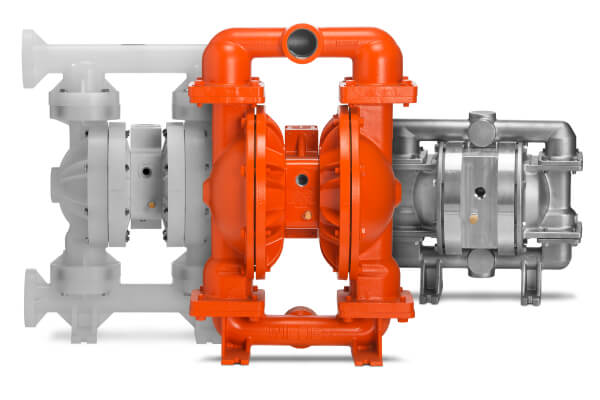

Product Description

As part of the Wilden® Pro-Flo® Series of AODD pumps, this pump is designed for basic general industrial applications with good flow, reliability and air consumption. It utilizes a clamped-band design for easy assembly and disassembly. This robust combination is perfect for applications where reliable operation and consistent performance maintenance are required, including dewatering, paint & coatings and ceramics.

CE Mark (Conformité Européene – European Conformity)

Wilden Pump & Engineering LLC has met the criteria for placing the CE mark on our product line. On December 3, 1999, Wilden fully self-certified its product line by meeting all the regulations of the Machinery and PED (Pressure Equipment) Directives. Every pump manufactured by Wilden will now receive the CE mark. Each pump box will also include a Safety Supplement manual in the eleven official languages of the European Community. This CE mark certification is indicative of Wilden’s pledge to providing our distributor network with all the sales tools necessary to excel in a global economy.