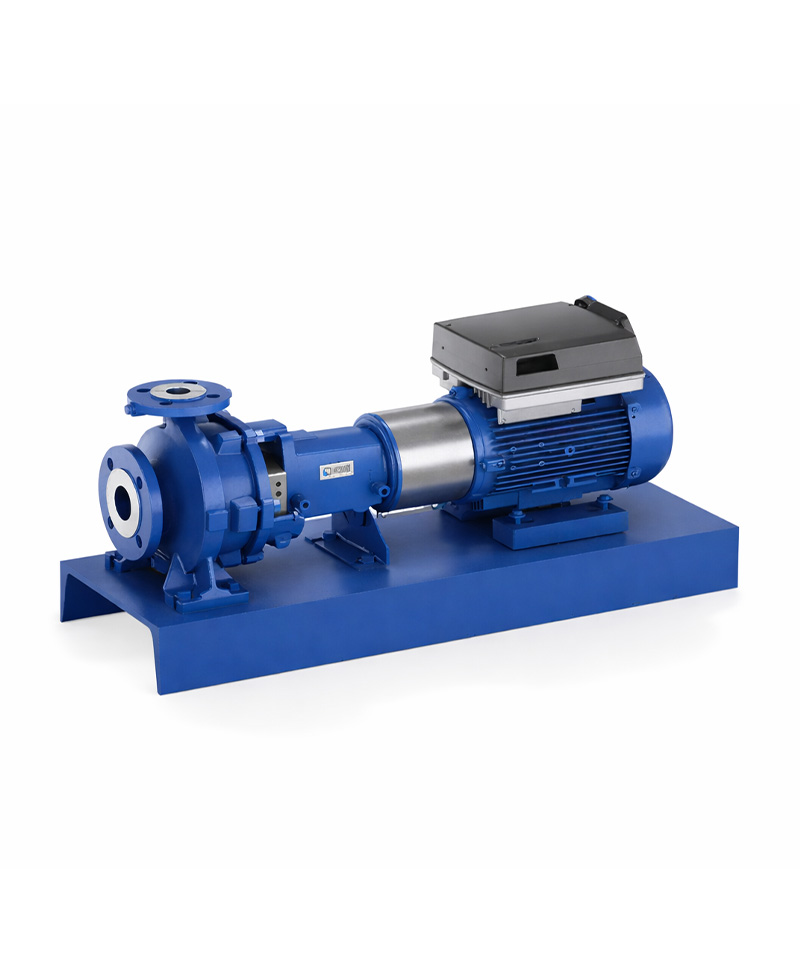

Product Description

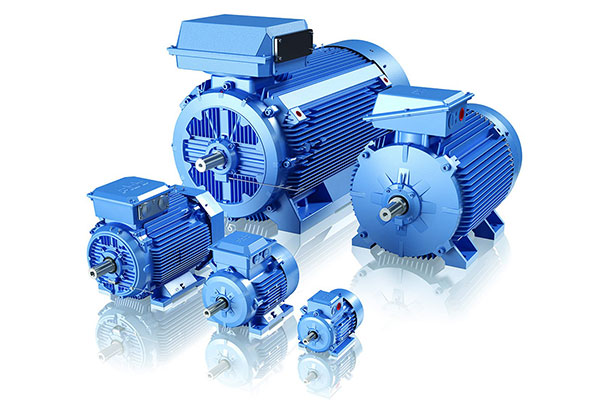

Single-stage volute casing pump in back pull-out design, with ratings and main dimensions to EN 733, with IEC-compatible power drive system comprising PumpDrive 2 and KSB SuPremE® motor or PumpDrive 3 (efficiency class IE4/IE5 to IEC TS 60034-2-3:2016) and motor-integrated frequency inverter. The pump is designed with replaceable casing wear rings, closed radial impeller with multiply curved vanes, single mechanical seal or double mechanical seals to EN 12756, shaft equipped with replaceable shaft protecting sleeve in the shaft seal area. The back pull-out design allows the coupling, bearing brackets and impeller to be dismantled without the need to disconnect the pump casing from the piping. Motor mounting points in accordance with IEC 60072, envelope dimensions in accordance with DIN V 42673 (07-2011). ATEX-compliant version available. Well ahead of the ErP Directive’s efficiency requirements.