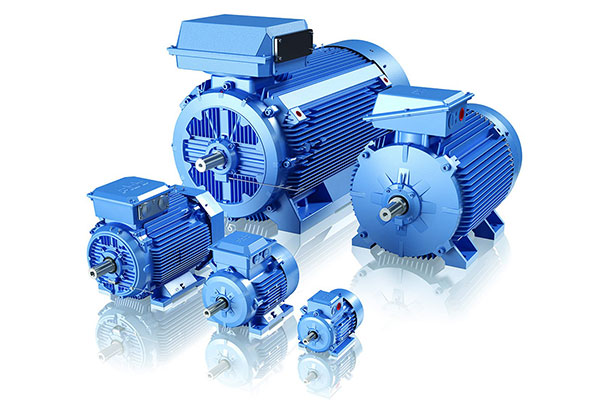

Product Description

Their enclosed rotor design ensures enhanced durability, while optimized electromagnetic characteristics provide high power density and energy efficiency. Suitable for applications requiring continuous duty and stable performance—such as pumps, compressors, fans, and conveyors—these motors offer a cost-effective and low-maintenance solution for demanding environments.